|

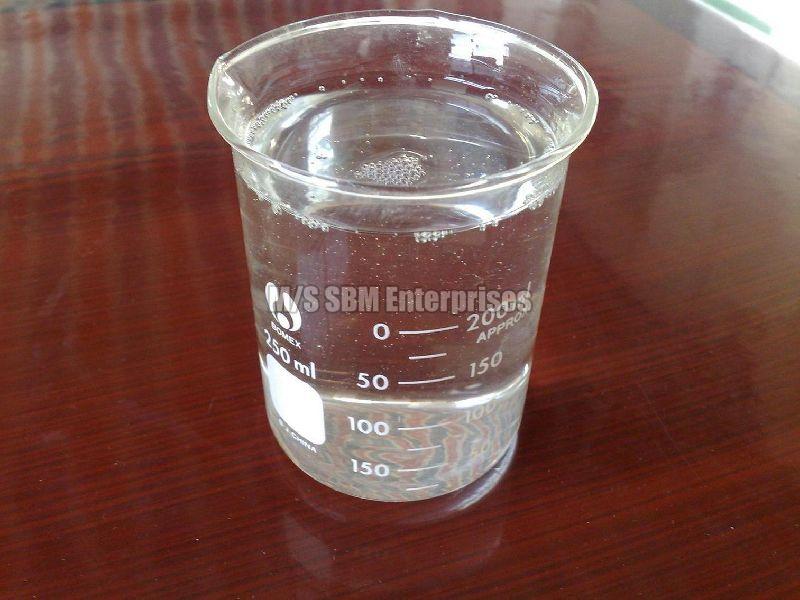

Sodium silicate popularly known as soluble glass or water glass can be described as a compound that includes silica and sodium oxide. The thickness of sodium silicate differs as per the ratios of silica and sodium oxide used. It is also called as an alkaline material. When it is mixed with water or heated at pressure it turns either colorless, syrup type liquid, or glass type powder. It has been widely used in various industries that may include manufacturing units and agriculture sector. It is also used in industries in the form of adhesives, detergents, as an essential element in cleaning compound, cements, chemicals, and catalyst bases, among others. It is worth noting that the various features and useful characteristics of soluble silicates can be used for effectively solving several problems occurring in the industrial and chemical processes.

Given below are some of the uses of sodium silicate that can be described as:

1. Solutions of sodium silicate have been widely used as an important element in the drying procedure while manufacturing the detergent powder for several years. Sodium silicate solutions are conveniently mixed with the detergent paste and assist in controlling the thickness of the detergent powder production of any desired density. It has also been used as a binder to provide the desired degree of stiffness to the detergent particles san impacting their solubility in water.

2. Sodium silicate is also used in the form of liquid as an adhesive in the manufacturing applications. It helps in binding various objects that may include paper cores for paper towels, fiber drums, corrugated board, tissue paper for toilet, and paperboard laminates among others. The liquid sodium silicate is usually applied with the assistance of a transfer roller by moving the watery solution on the material surface or by submerging the material in adhesive solution. A few people choose sodium silicate in the form of an adhesive as it is quite economical and environment friendly.

3. Sodium silicate is also used by potters and ceramics manufacturers all across the globe. They use it in the form of a deflocculent also known as a thinning substance. Sodium silicate is mixed with slip that is thin liquid clay used for attaching pieces of unfired ceramics or greenware. For instance, an expert potter tends to coat the corners of a cup handle before attaching it to the cup. The mixture of sodium silicate brings down the quantity of water required to manufacture the slip. And, it leads to reduced shrinkage during the firing procedure. Consequently, lesser pieces will be destroyed during the firing process. It is worth noting that sodium silicate powder should be used in a 1:1 ratio with water for this application.

4. Sodium silicate has emerged as one of the essential raw materials used for the synthetic production of silica gel. Silica gel has become an efficient desiccant or drying agent. Silica gel can be identified by irregularly shaped hard crystals.

Therefore, we may conclude here that you must always purchase sodium silicate from renowned sodium silicate suppliers in India.

|

Leave a Comment